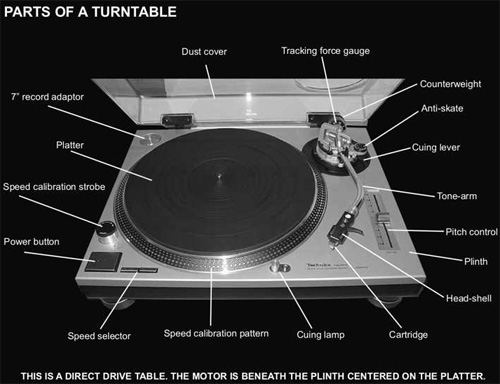

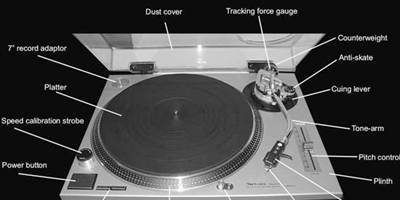

The turntable has several basic components including the plinth (base), the revolving platter, the tone arm, the cartridge and stylus, and the mechanical and electronic components to make it all work.

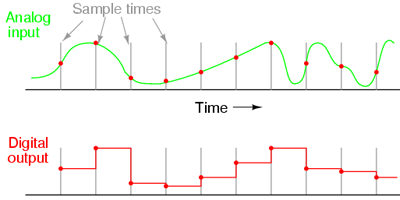

The turntable has one purpose which is to produce an accurate electrical signal to the phono preamp. That is easier said than done and many technical issues must be overcome. Some technical issues are related to the turntable itself while others are environmentally related.

I will describe a basic turntable from an operational point of view. Please realize that to overcome all of the technical issues that occur, inventive engineers and designers have developed some pretty unusual methods for counteracting and solving the problems. As such, a extraordinarily wide range of turntables have been designed and built.

But they all get back to just a couple of basic issues;

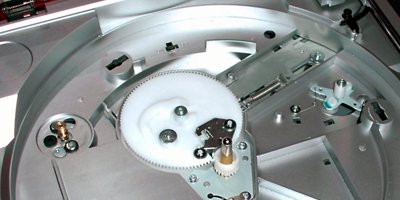

Maintaining 33 1/3 rpm as closely as possible, and the elimination of all extraneous noises while generating a “perfect signal”. The electric motor that causes the turntable (platter) to spin is a primary cause of extraneous noise. So engineers have used a variety of methods (belt drive, direct drive, idler wheel drive, or other means) to reduce or eliminated this unwanted noise.

All methods have their benefits and drawbacks. One design feature that is widely accepted as a good thing is a very heavy platter with very good bearings. This keeps the turntable moving at a constant speed as it is less susceptible to speed variations. A good weight bearing method (bearings) with low friction and noise help to keep the entire rotating mass smooth and quiet.

Sign Up For Our Newsletter

Sign Up For Our Newsletter

Found your site on yahoo today and really liked it.. I bookmarked it and will be back to check it out some more later.